ESI SysWeld 2019.0 x64 | 979 MB | Language: English

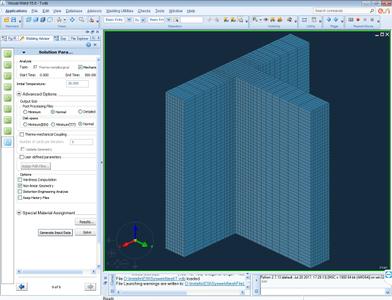

ESI Group is a leading innovator in Virtual Prototyping software and services for manufacturing industries, announces the release of SysWeld 2019.0, ESI’s software solution for Assembly, Welding and Heat Treatment.

Highlights of the release:

Visual Weld and HT:

Fast, intuitive and easy-to-use welding and heat treatment simulation tool which covers all activities of the welding & heat treatment engineer. Some key new functionalities are:

– Sub-assembly management (mapping on deformed geometry, mapping with initialization of physical properties, mapping with geometrical transformation…)

– Clamping condition based on the current deformed geometry (not the initial one)

– Update in contact parameters to improve convergence performance

– Heat treatment – machining chaining solution for part distortion

Visual Assembly:

New generation, easy-to-use assembly simulation for distortion control which:

– Covers complete car body manufacturing chain starting from the stamped part to pre-positioning to holding/clamping and finally welding/joining. Inheriting details of the "as manufactured" components from the press shop, visual assembly simulates step by step the entire assembly and welding process chain in the body shop.

– Covers large welded assemblies with thick plates and multi-pass welds, which are common in the shipbuilding industry. Aimed at shop floor production, the software can deliver the optimization of a weld sequence plan thanks to a streamlined and intuitive interface, offering dedicated automatic meshing functionalities and easy model set-up.

ESI SysWeld is the most accurate Finite Element Analysis (FEA) multi-physics software on the market to simulate thermal joining (arc, electron beam, laser, friction stir, spot welding) and heat treatment (carburizing, carbonitriding, quenching). SYSWELD accurately predicts material characteristics, residual stresses and distortions of structures. By accounting for all relevant manufacturing effects and enabling the transport of simulation results from one manufacturing step to the next, SYSWELD delivers a truly predictive end-to-end solution for the manufacturing of welded and assembled industrial parts.

These unique capabilities enable manufacturers in ground transportation and other industry sectors – aerospace, heavy industries and marine – to reduce product development costs and time to market and ensure process automation and optimization. For example, COMIL, a major bus manufacturer in Brazil, employed SYSWELD to manage to geometrical distortions induced by welding and assembly of a bus door frame.

Sysweld Visual Weld Spot Weld interface and Analysis

ESI Group, the French company listed in compartment B of NYSE Euronext Paris is a leading innovator in Virtual Prototyping software and services. Present in more than 40 countries, and addressing every major industrial sector, ESI Group employs about 1200 high-level specialists around the world.

Product: ESI SysWeld

Version: 2019.0 *

Supported Architectures: x64

Website Home Page : http://www.esi-group.com

Language: english

System Requirements: PC **

Supported Operating Systems: **

Size: 979.0 mb

Welding Simulation: Visual-Weld 14.5 and SYSWELD Solvers 2019.0

Heat Treatment Simulation: Visual-HT 14.5 and SYSWELD Solvers 2019.0

Assembly Simulation: Visual-Assembly 14.5 and Virtual Assembly Solver (CSM) 2018.5, for distortion control in:

– Body manufacturing for auto industry

– Thick plate and large welded assemblies for shipbuilding

– Welding Sequence Optimization with help of PAM-OPT 2019.0

Minimum Requirements:

Microsoft Windows 64-Bit Operating Systems:

– Windows 10 Version 1709

– Windows 8.1 with Update

– Windows 7 SP1 with latest hotfixes

– It is recommended to perform installation with administrative privileges.

– x64 compatible processors (Intel, AMD …).

– OpenText Exceed and Exceed 3D version 14 (for SYSWELD Solver GUI)

– 2 Gigabytes (Gb) of RAM (4 Gb recommended)

– Disk (free) space required: 2.6 Gb in the Program Files folder for complete installation (around 1.1 Gb for Assembly Solvers or 1.3 Gb for SYSWELD Solvers)